Poháněný držák pro technologii obrážení drážek a tvarů

M.T.'s broaching toolholder allows to realize key slots in an extremely shorter time compared with the other available technologies and without a double set up on two different machines, as all the machining is performed on the turret lathe.

Therefore, important reductions on the cycle times can be obtained.

It is possible to machine keyways up to 12mm wide and also special profiles like internal gears and seats of external teeth.

M.T. is at your disposal to realize special tools for our slotting toolholders, which allows to optimize the machining parameters and reduce the slotting times. In any case, our slotting toolholder can be used also with the inserts broaching tools that can be easily found on the market.

Our Technical Department is at your disposal to support you during the definition of the suitable tool, as well as to the definition of the machining parameters.

Product features

M.T.'s broaching toolholder has the following main features:

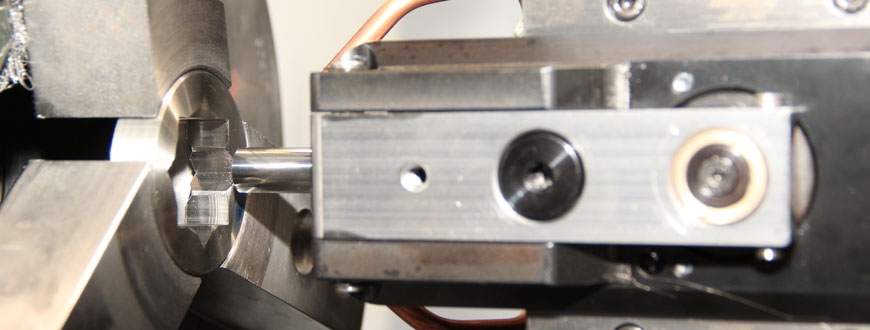

- With M.T.'s broaching tool, the tool is in contact with the part only during the machining stroke. A dedicated mechanism operates the lifting of the tool during the return stroke, maximizing the life of the tool.

- Two version with fixed stroke of 50 or 25 mm, corresponding to a maximum keyway length of 47 or 22 mm.

- The reduction ratio of 1:4 (1.600 rpm corresponds to 400 strokes per minute) allows the machining on hard material also with limited power available at the driven toolholder

- Double guideway design, maximum stability during broaching operation

M.T.'s broaching toolholder is available for many machine models, from NL/NZ Mori Seiki machines to smaller machine models like Biglia, Nakamura-Tome (WT150/Supermill), Okuma (LB3000/4000/LT2000), VDI40 (axial and radial tooldisc), Doosan (BMT-55/65) and Takisawa.

Search for the solution suitable for your application on our online catalogue!